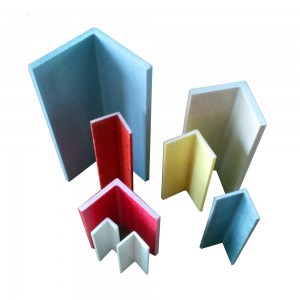

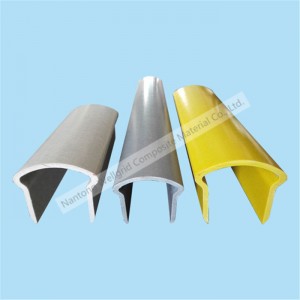

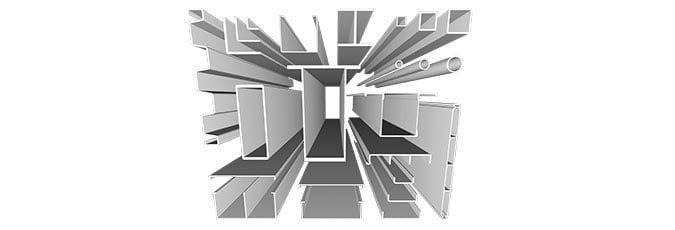

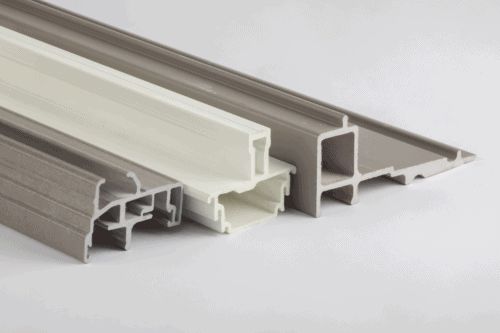

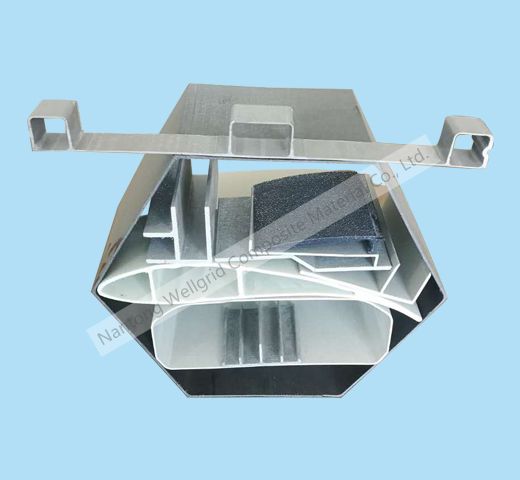

FRP Pultruded Profile

WELLGRID is your engineering partner for FRP handrail, guardrail, ladder and structural product needs. Our professional engineering and drafting team can help you find the right solution that meets your needs for longevity, safety and cost.

Features

Light to weight

Pound-for-pound, Our pultruded fiberglass structural shapes are stronger than steel in the lengthwise direction. Our FRP weighs up to 75% less than steel and 30% less than aluminum – ideal when weight and performance counts.

Easy Installation

FRP costs on average 20% less than steel to install with less down time, less equipment, and less specialized labor. Avoid costly specialized labor and heavy equipment, and speed the construction process by using pultruded structural products.

Chemical Corrosion

Fiber reinforced polymer (FRP) composites offer resistance to a broad range of chemicals and harsh environments. We offers a full corrosion resistance guide to ensure the performance of its products in some of the toughest conditions.

Maintenance Free

FRP is durable and impact resistant. It will not dent or deform like metals. Resists rot and corrosion, eliminating the need for constant maintenance. This combination of performance and durability offers the ideal solution in numerous applications.

Long Service life

Our products provide outstanding durability and corrosion resistance in demanding applications, providing improved product life over traditional materials. The longevity of FRP products provide cost savings over the product’s life cycle. Installed costs are less because of the ease of installation. Maintenance expenses reduce because there is less downtime in areas requiring maintenance, and the costs of removing, disposing, and replacing the corroded steel grating is eliminated.

High Strength

FRP has a high strength-to-weight ratio when compared to traditional materials like metal, concrete and wood. FRP gratings can be designed to be strong enough to carry vehicular loads while still being less than one-half the weight of steel grating.

Impact Resistant

FRP can withstand major impacts with negligible damage. We offers extremely durable gratings to satisfy even the most stringent impact requirements.

Electrically & Thermally Non-Conductive

FRP is electrically non-conductive leading to increased safety compared to conductive materials (i.e., metal). FRP also has low thermal conductivity (heat transfer occurs at a lower rate), resulting in a more comfortable product surface when physical contact occurs.

Fire Retardant

FRP products are engineered to have a flame spread of 25 or less as tested in accordance with ASTM E-84. They also meet the self-extinguishing requirements of ASTM D-635.

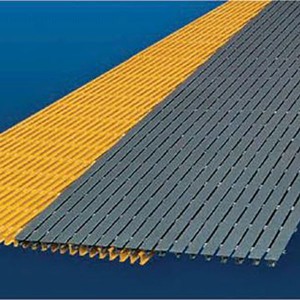

Slip Resistant

Our molded and pultruded gratings and stairway products provide superior, slip resistant footing in wet and oily environments. Steel becomes slippery when oily or wet, but our gratings have a higher friction factory and remain safe even when wet.

Our slip resistant products increase safety for workers which will lead to fewer workplace accidents and a reduction of injury-associated costs.

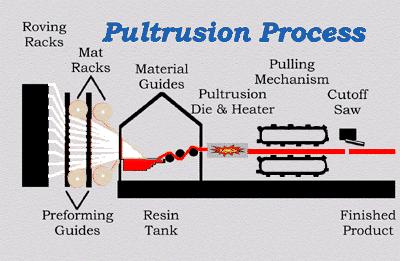

Specifications

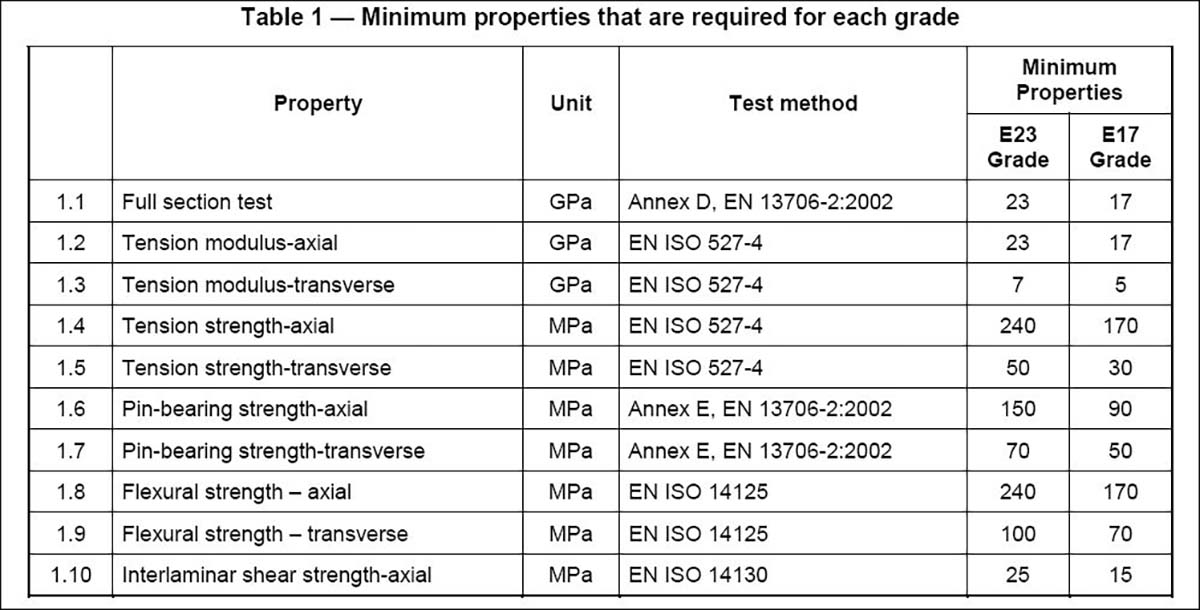

Our pultrusion structural profiles have high strength and modulus in lengthwise (LW) and crosswise (CW) and meet the relevant Europe and America standards; they are used widely abroad in cooling tower, power industries. Please contact us for having details for the pultrusion structural profiles.

We supply FRP pultrusion structural profiles meet EN 13706 standard with below properties.

|

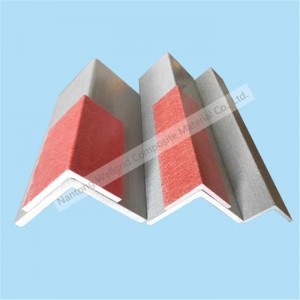

Angle |

H(mm) |

B(mm) |

T1(mm) |

T2(mm) |

(mm²) |

(g/m) |

|

25 |

25 |

3.2 |

3.2 |

153 |

290 |

|

|

30 |

20 |

4 |

4 |

184 |

350 |

|

|

30 |

30 |

3 |

3 |

171 |

325 |

|

|

40 |

22 |

4 |

4 |

232 |

440 |

|

|

40 |

40 |

4 |

4 |

304 |

578 |

|

|

40 |

40 |

8 |

8 |

574 |

1090 |

|

|

50 |

50 |

5 |

5 |

475 |

902 |

|

|

50 |

50 |

6.4 |

6.4 |

604 |

1147 |

|

|

76 |

76 |

6.4 |

6.4 |

940 |

1786 |

|

|

76 |

76 |

9.5 |

9.5 |

1367 |

2597 |

|

|

101 |

101 |

6.4 |

6.4 |

1253 |

2380 |

|

|

101 |

101 |

9.5 |

9.5 |

1850 |

3515 |

|

|

101 |

101 |

12.7 |

12.7 |

2425 |

4607 |

|

|

152 |

152 |

9.5 |

9.5 |

2815 |

5348 |

|

|

152 |

152 |

12.7 |

12.7 |

3730 |

7087 |

|

|

220 |

72 |

8 |

8 |

2274 |

4320 |

|

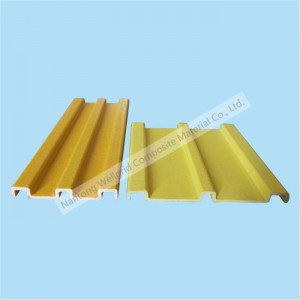

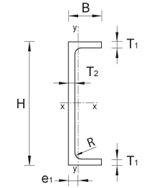

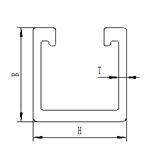

Channel |

H(mm) |

B(mm) |

T1(mm) |

T2(mm) |

(mm²) |

(g/m) |

|

|

40 |

20 |

4 |

4 |

289 |

550 |

|

50 |

14 |

3 |

3 |

220 |

418 |

|

|

75 |

25 |

5 |

5 |

576 |

1094 |

|

|

76 |

38 |

6.4 |

6.4 |

901 |

1712 |

|

|

80 |

30 |

3.1 |

3.1 |

405 |

770 |

|

|

101 |

35 |

3.2 |

3.2 |

529 |

1006 |

|

|

101 |

48 |

3.2 |

3.2 |

613 |

1165 |

|

|

101 |

30 |

6.4 |

6.4 |

937 |

1780 |

|

|

101 |

44 |

6.4 |

6.4 |

1116 |

2120 |

|

|

150 |

50 |

6 |

6 |

1426 |

2710 |

|

|

152 |

35 |

4.8 |

4.8 |

1019 |

1937 |

|

|

152 |

48 |

4.8 |

4.8 |

1142 |

2170 |

|

|

152 |

42 |

6.4 |

6.4 |

1368 |

2600 |

|

|

152 |

45 |

8 |

8 |

1835 |

3486 |

|

|

152 |

42 |

9.5 |

9.5 |

2077 |

3946 |

|

|

178 |

60 |

6.4 |

6.4 |

1841 |

3498 |

|

|

203 |

55 |

6.4 |

6.4 |

1911 |

3630 |

|

|

203 |

55 |

9.5 |

9.5 |

2836 |

5388 |

|

|

254 |

72 |

12.7 |

12.7 |

4794 |

9108 |

|

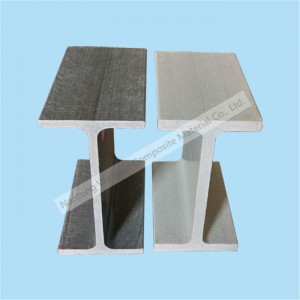

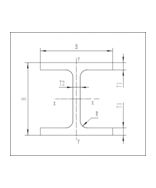

I Beam |

H(mm) |

B(mm) |

T1(mm) |

T2(mm) |

(mm²) |

(g/m) |

|

25 |

15 |

4 |

4 |

201 |

381 |

|

38 |

15 |

4 |

4 |

253 |

480 |

|

|

50 |

15 |

4 |

4 |

301 |

571 |

|

|

76 |

38 |

6.4 |

6.4 |

921 |

1749 |

|

|

102 |

51 |

6.4 |

6.4 |

1263 |

2400 |

|

|

152 |

76 |

6.4 |

6.4 |

1889 |

3590 |

|

|

152 |

76 |

9.5 |

9.5 |

2800 |

5320 |

|

|

203 |

101 |

9.5 |

9.5 |

3821 |

7260 |

|

|

203 |

101 |

12.7 |

12.7 |

5079 |

9650 |

|

|

254 |

127 |

9.5 |

9.5 |

4737 |

9000 |

|

|

254 |

127 |

12.7 |

12.7 |

6289 |

11950 |

|

|

305 |

152 |

9.5 |

9.5 |

5653 |

10740 |

|

|

305 |

152 |

12.7 |

12.7 |

7526 |

14300 |

|

WFB Beam |

H(mm) |

B(mm) |

T1(mm) |

T2(mm) |

(mm²) |

(g/m) |

|

76 |

76 |

6.4 |

6.4 |

1411 |

2680 |

|

102 |

102 |

6.4 |

6.4 |

1907 |

3623 |

|

|

100 |

100 |

8 |

8 |

2342 |

4450 |

|

|

152 |

152 |

6.4 |

6.4 |

2867 |

5447 |

|

|

152 |

152 |

9.5 |

9.5 |

4250 |

8075 |

|

|

203 |

203 |

9.5 |

9.5 |

5709 |

10847 |

|

|

203 |

203 |

12.7 |

12.7 |

7558 |

14360 |

|

|

254 |

254 |

9.5 |

9.5 |

7176 |

13634 |

|

|

254 |

254 |

12.7 |

12.7 |

9501 |

18051 |

|

|

305 |

305 |

9.5 |

9.5 |

8684 |

16500 |

|

|

305 |

305 |

12.7 |

12.7 |

11316 |

21500 |

|

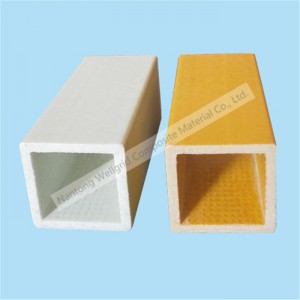

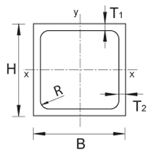

Square tube |

H(mm) |

B(mm) |

T1(mm) |

T2(mm) |

(mm²) |

(g/m) |

|

15 |

15 |

2.5 |

2.5 |

125 |

237 |

|

|

25.4 |

25.4 |

3.2 |

3.2 |

282 |

535 |

|

|

30 |

30 |

5 |

5 |

500 |

950 |

|

|

38 |

38 |

3.2 |

3.2 |

463 |

880 |

|

|

38 |

38 |

6.4 |

6.4 |

811 |

1540 |

|

|

40 |

40 |

4 |

4 |

608 |

1155 |

|

|

40 |

40 |

6 |

6 |

816 |

1550 |

|

|

44 |

44 |

3.2 |

3.2 |

521 |

990 |

|

|

44 |

44 |

6.4 |

6.4 |

963 |

1830 |

|

|

45 |

45 |

4 |

4 |

655 |

1245 |

|

|

50 |

25 |

4 |

4 |

537 |

1020 |

|

|

50 |

50 |

4 |

4 |

750 |

1425 |

|

|

50 |

50 |

5 |

5 |

914 |

1736 |

|

|

50 |

50 |

6.4 |

6.4 |

1130 |

2147 |

|

|

54 |

54 |

5 |

5 |

979 |

1860 |

|

|

60 |

60 |

5 |

5 |

1100 |

2090 |

|

|

76 |

38 |

4 |

4 |

842 |

1600 |

|

|

76 |

76 |

6.4 |

6.4 |

1795 |

3410 |

|

|

76 |

76 |

9.5 |

9.5 |

2532 |

4810 |

|

|

101 |

51 |

6.4 |

6.4 |

1779 |

3380 |

|

|

101 |

76 |

6.4 |

6.4 |

2142 |

4070 |

|

|

101 |

101 |

6.4 |

6.4 |

2421 |

4600 |

|

|

101 |

101 |

8 |

8 |

2995 |

5690 |

|

|

130 |

130 |

9 |

9 |

4353 |

8270 |

|

|

150 |

150 |

5 |

5 |

2947 |

5600 |

|

|

150 |

150 |

10 |

10 |

5674 |

10780 |

|

|

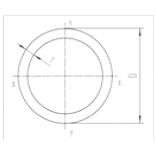

Round tube |

D1(mm) |

D2(mm) |

T(mm) |

(mm²) |

(g/m) |

|

|

19 |

14 |

2.5 |

128 |

245 |

|

24 |

19 |

2.5 |

168 |

320 |

|

|

25.4 |

20.4 |

2.5 |

180 |

342 |

|

|

30 |

24 |

3 |

254 |

482 |

|

|

32 |

26 |

3 |

273 |

518 |

|

|

40 |

32 |

4 |

452 |

858 |

|

|

50 |

42 |

4 |

578 |

1098 |

|

|

50 |

40 |

5 |

707 |

1343 |

|

|

50 |

37.2 |

6.4 |

877 |

1666 |

|

|

65 |

52.2 |

6.4 |

1178 |

2220 |

|

|

76 |

63.2 |

6.4 |

1399 |

2658 |

|

|

101 |

85 |

8 |

2337 |

4440 |

|

Solid round |

D(mm) |

(mm²) |

(g/m) |

|

|

7 |

38 |

72 |

|

|

8 |

50 |

95 |

||

|

10 |

79 |

150 |

||

|

12 |

113 |

215 |

||

|

15 |

177 |

336 |

||

|

18 |

254 |

483 |

||

|

20 |

314 |

597 |

||

|

25 |

491 |

933 |

||

|

38 |

1133 |

2267 |

||

|

Kick plate |

B(mm) |

H(mm) |

T(mm) |

(mm²) |

(g/m) |

|

100 |

12 |

3 |

461 |

875 |

|

100 |

15 |

4 |

579 |

1100 |

|

|

150 |

12 |

3 |

589 |

1120 |