Manufacturer Of Cutting Fiberglass Grating - High Quality FRP GRP Pultruded Grating – WellGrid

Manufacturer Of Cutting Fiberglass Grating - High Quality FRP GRP Pultruded Grating – WellGrid Detail:

FRP Pultruded Grating Availability

|

No. |

Type |

Thickness (mm) |

Open area (%) |

Bearing Bar Dimensions (mm) |

Center line distance |

Weight (kg/m2) |

||

|

Height |

Width top |

Wall thickness |

||||||

|

1 |

I-4010 |

25.4 |

40 |

25.4 |

15.2 |

4 |

25.4 |

18.5 |

|

2 |

I-5010 |

25.4 |

50 |

25.4 |

15.2 |

4 |

30.5 |

15.8 |

|

3 |

I-6010 |

25.4 |

60 |

25.4 |

15.2 |

4 |

38.1 |

13.1 |

|

4 |

I-4015 |

38.1 |

40 |

38.1 |

15.2 |

4 |

25.4 |

22.4 |

|

5 |

I-5015 |

38.1 |

50 |

38.1 |

15.2 |

4 |

30.5 |

19.1 |

|

6 |

I-6015 |

38.1 |

60 |

38.1 |

15.2 |

4 |

38.1 |

16.1 |

|

7 |

T-1810 |

25.4 |

18 |

25.4 |

41.2 |

4 |

50.8 |

14.0 |

|

8 |

T-3310 |

25.4 |

33 |

25.4 |

38.1 |

4 |

50.8 |

12.2 |

|

9 |

T-3810 |

25.4 |

38 |

25.4 |

38.1 |

4 |

61 |

11.2 |

|

10 |

T-3320 |

50.8 |

33 |

50.8 |

25.4 |

4 |

38.1 |

19.5 |

|

11 |

T-5020 |

50.8 |

50 |

50.8 |

25.4 |

4 |

50.8 |

15.2 |

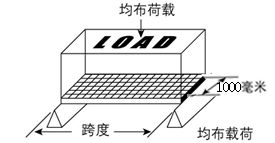

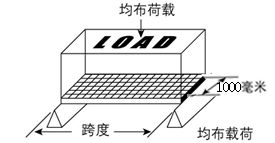

Loading Table

FRP Pultruded Grating Loading Table

Pultruded Grating T-3310

Pultruded I-5010

Pultruded Grating I-5015

Pultruded Grating T-3320

Pultruded Grating T-3310

|

span |

Line load (kg/m) |

Recommended max. load |

Ultimate load |

||||

|

149 |

373 |

745 |

1148 |

1490 |

|||

|

457 |

0.36 |

0.86 |

1.72 |

2.58 |

3.45 |

1720 |

8600 |

|

610 |

0.79 |

1.94 |

3.89 |

5.81 |

7.75 |

1286 |

6430 |

|

914 |

2.41 |

6.01 |

– |

– |

– |

840 |

4169 |

|

1219 |

5.38 |

13.60 |

– |

– |

– |

602 |

3010 |

|

span |

Uniform load (kg/m2) |

Recommended max. load |

Ultimate load |

||||

|

488 |

1220 |

2440 |

3660 |

4880 |

|||

|

457 |

0.32 |

0.98 |

1.62 |

2.26 |

3.25 |

7520 |

37620 |

|

610 |

0.99 |

2.28 |

4.86 |

6.80 |

9.70 |

4220 |

21090 |

|

914 |

4.51 |

– |

– |

– |

– |

1830 |

9160 |

|

1219 |

– |

– |

– |

– |

– |

– |

– |

Pultruded I-5010

|

span |

Line load (kg/m) |

Recommended max. load |

Ultimate load |

||||

|

149 |

373 |

745 |

1148 |

1490 |

|||

|

457 |

– |

– |

2.54 |

3.59 |

4.80 |

2760 |

13800 |

|

610 |

– |

1.90 |

4.08 |

6.05 |

8.15 |

2150 |

10760 |

|

914 |

2.25 |

5.71 |

11.70 |

17.50 |

23.25 |

1436 |

7180 |

|

1219 |

5.05 |

12.70 |

25.60 |

38.20 |

50.98 |

1070 |

5368 |

|

span |

Uniform load (kg/m2) |

Recommended max. load |

Ultimate load |

||||

|

488 |

1220 |

2440 |

3660 |

4880 |

|||

|

457 |

0.50 |

1.60 |

2.65 |

3.80 |

4.57 |

12100 |

60520 |

|

610 |

1.26 |

3.13 |

5.30 |

7.37 |

10.40 |

7080 |

35430 |

|

914 |

4.56 |

13.10 |

– |

– |

– |

3140 |

15716 |

|

1219 |

13.68 |

– |

– |

– |

– |

1760 |

8809 |

Pultruded Grating I-5015

|

span |

Line load (kg/m) |

Recommended max. load |

Ultimate load |

||||

|

149 |

373 |

745 |

1148 |

1490 |

|||

|

457 |

– |

0.50 |

0.99 |

1.50 |

1.75 |

4370 |

21856 |

|

610 |

0.26 |

0.89 |

1.50 |

2.30 |

3.28 |

3280 |

16400 |

|

914 |

0.74 |

1.90 |

3.80 |

5.55 |

7.60 |

2116 |

10580 |

|

1219 |

1.76 |

4.18 |

8.36 |

12.46 |

16.48 |

1514 |

7570 |

|

span |

Uniform load (kg/m2) |

Recommended max. load |

Ultimate load |

||||

|

488 |

1220 |

2440 |

3660 |

4880 |

|||

|

457 |

0.25 |

0.64 |

1.02 |

1.40 |

2.00 |

19100 |

95560 |

|

610 |

0.5 |

1.27 |

2.18 |

2.94 |

4.04 |

10780 |

53900 |

|

914 |

1.78 |

4.56 |

7.66 |

10.68 |

15.20 |

4630 |

23168 |

|

1219 |

4.56 |

12.60 |

– |

– |

– |

2490 |

12460 |

Pultruded Grating T-3320

|

span |

Line load (kg/m) |

Recommended max. load |

Ultimate load |

||||

|

149 |

373 |

745 |

1148 |

1490 |

|||

|

457 |

– |

– |

– |

– |

– |

– |

– |

|

610 |

– |

– |

0.51 |

0.74 |

1.06 |

3375 |

16876 |

|

914 |

– |

0.62 |

1.28 |

1.76 |

2.30 |

1500 |

7498 |

|

1219 |

0.49 |

1.27 |

2.26 |

3.52 |

4.82 |

845 |

4228 |

|

span |

Uniform load (kg/m2) |

Recommended max. load |

Ultimate load |

||||

|

488 |

976 |

2440 |

3660 |

4880 |

|||

|

457 |

– |

– |

– |

– |

– |

– |

– |

|

610 |

– |

0.38 |

0.50 |

0.64 |

1.000 |

11080 |

55400 |

|

914 |

0.52 |

1.16 |

1.90 |

2.68 |

3.80 |

7380 |

36900 |

|

1219 |

1.28 |

3.40 |

5.70 |

8.12 |

11.66 |

5570 |

27861 |

| Notes: 1, Safety factor is 5; 2, Ultimate load is the grating break load; 3, This table is only for information, resins and grating surfaces influence the grating loading property. | |||||||

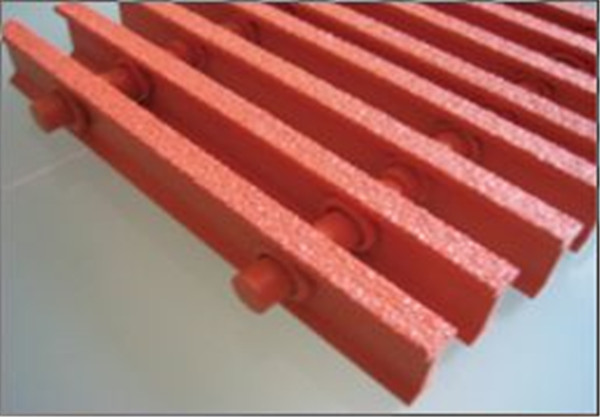

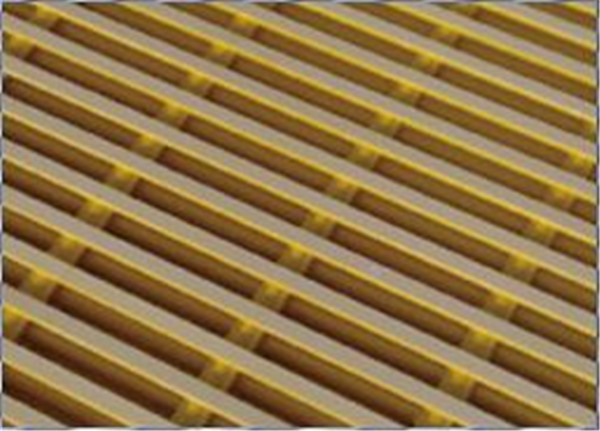

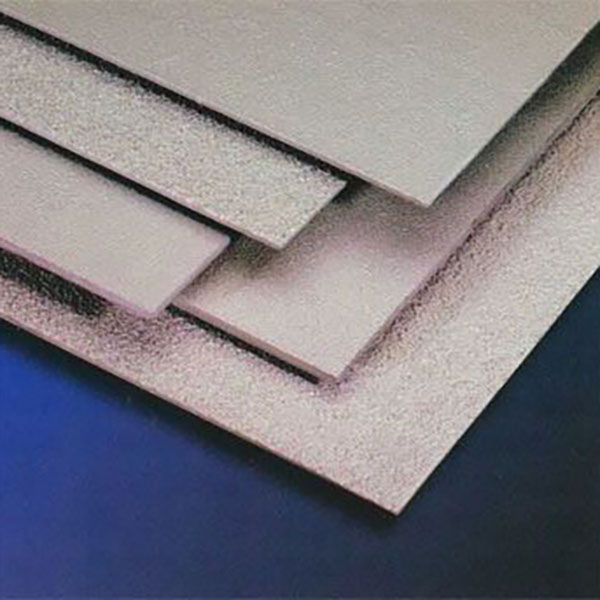

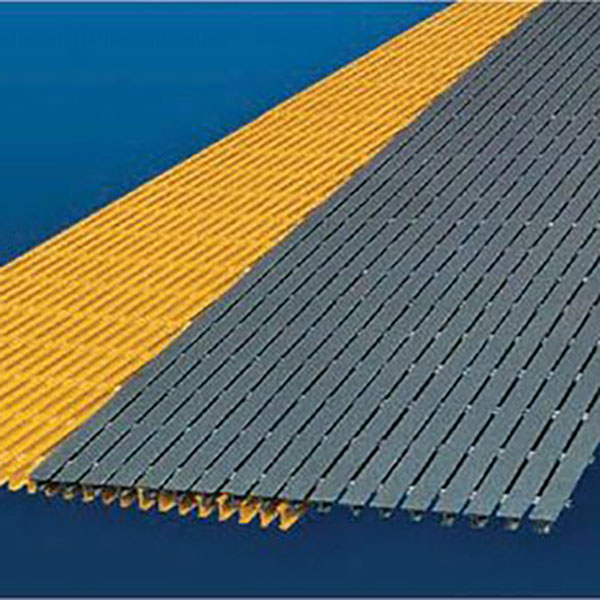

FRP Pultruded Grating Surface

|

Real |

Surface |

Service |

|

Corrugated surface (No grit) |

Anti-skid, easy clean |

|

|

Grit surface |

Anti-skid and good abrasion (The grit could be fine, middle and coarse) |

|

|

Smooth surface |

Free clean, contaminant non stay |

|

|

Chequer cover surface |

Anti-skid, easy clean, odour isolation |

|

|

Grit cover surface |

Anti-skid, good abrasion (The grit could be fine, middle and coarse), odour isolation |

Standard Resin Systems

|

ONFR |

Polyester resin system, Good corrosion resistance, Non fire resistance; |

|

OFR |

Polyester resin system, Good corrosion resistance, Fire resistance ASTM E-84 Class 1; |

|

ISOFR |

Premium grade Isophthalic Polyester resin system, excellent corrosion resistance, Fire resistance ASTM E-84 Class 1; |

|

VEFR |

Vinyl Ester resin system, Maximum corrosion resistance, Fire resistance ASTM E-84 Class 1; |

|

PHE |

Phenolic resin system, High temperature service, Low flame spread index, low smoke developed index and low toxicity. |

Chemical Properties

FRP Pultruded Grating Chemical Properties Guide:

|

Chemicals |

Concentration |

Maximum service temperature |

||

|

Vinyl ester resin |

Iso resin |

Ortho resin |

||

| Acetic acid |

50 |

82 |

30 |

20 |

| Chromic acid |

20 |

38 |

No |

No |

| Nitric acid |

5 |

70 |

48 |

25 |

| Phosphoric acid |

85 |

100 |

65 |

No |

| Sulfuric acid |

25 |

100 |

52 |

20 |

| Hydrochloric acid |

<10 |

100 |

52 |

No |

|

20 |

90 |

38 |

No |

|

|

37 |

65 |

No |

No |

|

| Hydrotropic acid |

25 |

93 |

38 |

No |

| Lactic acid |

100 |

100 |

52 |

40 |

| Benzoic acid |

All |

100 |

65 |

—— |

| Aluminum hydroxide |

All |

82 |

45 |

No |

| Aqueous ammonia |

28 |

52 |

30 |

No |

| Sodium hydroxide |

10 |

65 |

20 |

No |

|

25 |

65 |

No |

No |

|

|

50 |

70 |

No |

No |

|

| Ammonium sulfate |

All |

100 |

60 |

50 |

| Ammonium chloride |

All |

100 |

82 |

60 |

| Ammonium bicarbonate |

All |

52 |

No |

No |

| Copper chloride |

All |

100 |

65 |

60 |

| Copper cyanide |

All |

100 |

No |

No |

| Ferric chloride |

All |

100 |

65 |

60 |

| Ferrous chloride |

All |

100 |

60 |

50 |

| Manganese sulfate |

All |

100 |

65 |

45 |

| Sodium cyanide |

All |

100 |

—— |

—— |

| Potassium nitrate |

All |

100 |

65 |

40 |

| Zinc sulfate |

All |

100 |

65 |

45 |

| potassium nitrate |

100 |

100 |

65 |

40 |

| Potassium dichromate |

100 |

100 |

60 |

40 |

| Ethylene glycol |

100 |

100 |

65 |

40 |

| Propylene glycol |

100 |

100 |

65 |

40 |

| Gasoline |

100 |

80 |

60 |

35 |

| Glucose |

100 |

100 |

38 |

No |

| Glycerin |

100 |

100 |

65 |

60 |

| Hydrogen peroxide |

30 |

38 |

— |

— |

| Dry chlorine gas |

100 |

82 |

38 |

No |

| Wet chlorine gas |

All |

82 |

No |

No |

| Vinegar |

100 |

100 |

65 |

30 |

| Distilled water |

100 |

93 |

60 |

25 |

| fresh water |

100 |

100 |

70 |

40 |

| Note: the “All” in concentration column refers to the chemical is saturated in water; and the “100” refers to pure chemicals. | ||||

Product detail pictures:

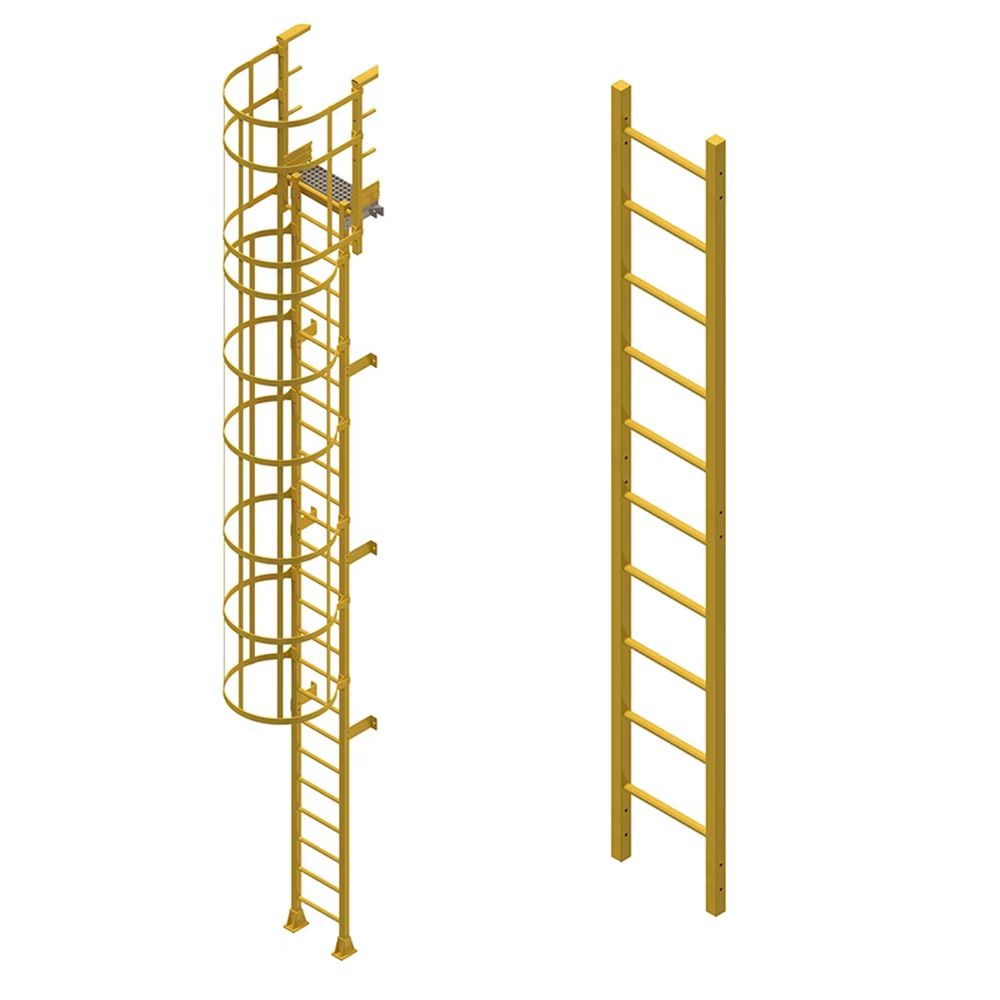

Related Product Guide:

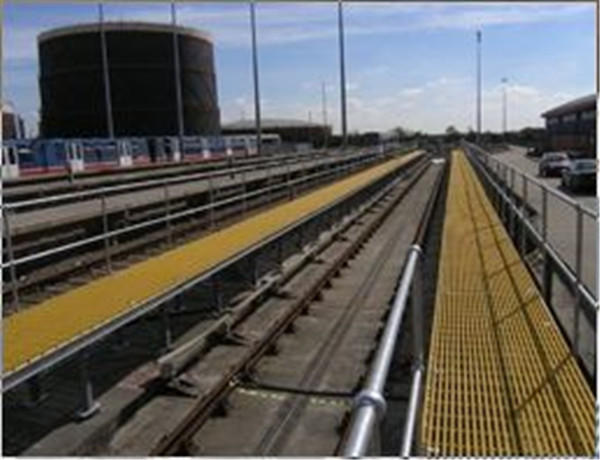

That has a positive and progressive attitude to customer's interest, our organization consistently improves our products quality to satisfy the demands of shoppers and further focuses on safety, reliability, environmental specifications, and innovation of Manufacturer Of Cutting Fiberglass Grating - High Quality FRP GRP Pultruded Grating – WellGrid , The product will supply to all over the world, such as: Doha, Madrid, Albania, We have been very responsible for all details on our customers order no matter on warranty quality, satisfied prices, quick delivery, on time communication, satisfied packing, easy payment terms, best shipment terms, after sales service etc. We provide one-stop service and best reliability to our every customers. We work hard with our customers, colleagues, workers to make a better future.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.