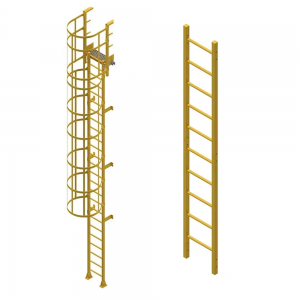

Introduce: The FRP (Fibre Reinforced Plastic) cage ladder system is a breakthrough innovation in ladder safety that will revolutionize industrial and commercial vertical access solutions. This ladder system combines the lightweight and corrosion-resistant properties of fiberglass with a rugged cage shell to provide unparalleled safety and durability. As industries increasingly focus on worker protection and regulatory compliance, the prospects for fiberglass cage ladder systems are expected to grow significantly.

Enhanced security and durability: The main advantage of fiberglass cage ladder systems is their ability to ensure worker safety. A sturdy fiberglass cage surrounds the ladder, providing users with a safe environment that minimizes the risk of falls and accidents. Additionally, the FRP material used in ladder construction is not electrically conductive, making it ideal for environments where electrical hazards exist. Additionally, the corrosion-resistant properties of FRP ensure the longevity of the ladder system, even in harsh industrial conditions.

Adaptability and versatility: Another key aspect of a fiberglass cage ladder system is its adaptability to a variety of industries and environments. From water and wastewater treatment plants to chemical plants and manufacturing facilities, this ladder system can meet the specific needs of different industries. Its lightweight nature makes transportation and installation hassle-free, while the flexibility of FRP enables customization to meet any height or configuration requirements. This versatility makes FRP cage ladder systems the solution of choice for companies looking for reliable, efficient access options.

Regulatory Compliance and Standards: In recent years, industry regulations and standards have placed a strong emphasis on employee safety, particularly when it comes to vertical access solutions. FRP cage ladder systems exceed these requirements, ensuring compliance with regulations such as OSHA (Occupational Safety and Health Administration) standards. By investing in this ladder system, companies can proactively meet safety guidelines and create a safer work environment, protecting employees and their reputations.

Future growth potential: As industries continue to prioritize employee safety and regulatory compliance, demand for advanced ladder systems such as fiberglass cage ladder systems is expected to grow steadily. Its ability to withstand harsh environments, lightweight design and cross-industry adaptability make it an attractive solution for many industries. Additionally, FRP’s durability and low maintenance requirements provide organizations with a cost-effective long-term investment.

In conclusion: Fiberglass cage ladder systems are becoming a game changer in the field of vertical access solutions. Its ability to combine safety, durability and adaptability makes it the first choice for industries looking to improve worker protection and regulatory compliance. As the demand for efficient and safe ladder systems continues to rise, fiberglass cage ladder systems have a bright future. By investing in this innovative solution, companies can achieve the dual goals of prioritizing employee safety while ensuring compliance with industry regulations.

Operating with a privately-owned company, Nantong Wellgrid Composite Material Co., Ltd. is situated in the port city of Nantong, Jiangsu Province, China and is neighbored to Shanghai. And Our production and technical engineers have more than 20 years of experience in the production and R & D of FRP products. We are committed to researching and producing products fiberglass cage ladder systems releated products, if you are interested in our company and our products, you can contact us.

Post time: Nov-06-2023