OEM Customized Heavy Duty Frp Grating - High Quality FRP GRP Pultruded Grating – WellGrid

OEM Customized Heavy Duty Frp Grating - High Quality FRP GRP Pultruded Grating – WellGrid Detail:

FRP Pultruded Grating Availability

|

No. |

Type |

Thickness (mm) |

Open area (%) |

Bearing Bar Dimensions (mm) |

Center line distance |

Weight (kg/m2) |

||

|

Height |

Width top |

Wall thickness |

||||||

|

1 |

I-4010 |

25.4 |

40 |

25.4 |

15.2 |

4 |

25.4 |

18.5 |

|

2 |

I-5010 |

25.4 |

50 |

25.4 |

15.2 |

4 |

30.5 |

15.8 |

|

3 |

I-6010 |

25.4 |

60 |

25.4 |

15.2 |

4 |

38.1 |

13.1 |

|

4 |

I-4015 |

38.1 |

40 |

38.1 |

15.2 |

4 |

25.4 |

22.4 |

|

5 |

I-5015 |

38.1 |

50 |

38.1 |

15.2 |

4 |

30.5 |

19.1 |

|

6 |

I-6015 |

38.1 |

60 |

38.1 |

15.2 |

4 |

38.1 |

16.1 |

|

7 |

T-1810 |

25.4 |

18 |

25.4 |

41.2 |

4 |

50.8 |

14.0 |

|

8 |

T-3310 |

25.4 |

33 |

25.4 |

38.1 |

4 |

50.8 |

12.2 |

|

9 |

T-3810 |

25.4 |

38 |

25.4 |

38.1 |

4 |

61 |

11.2 |

|

10 |

T-3320 |

50.8 |

33 |

50.8 |

25.4 |

4 |

38.1 |

19.5 |

|

11 |

T-5020 |

50.8 |

50 |

50.8 |

25.4 |

4 |

50.8 |

15.2 |

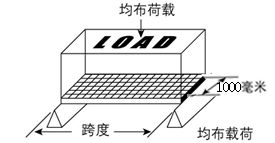

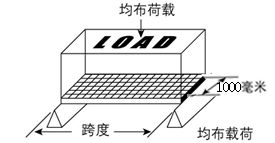

Loading Table

FRP Pultruded Grating Loading Table

Pultruded Grating T-3310

Pultruded I-5010

Pultruded Grating I-5015

Pultruded Grating T-3320

Pultruded Grating T-3310

|

span |

Line load (kg/m) |

Recommended max. load |

Ultimate load |

||||

|

149 |

373 |

745 |

1148 |

1490 |

|||

|

457 |

0.36 |

0.86 |

1.72 |

2.58 |

3.45 |

1720 |

8600 |

|

610 |

0.79 |

1.94 |

3.89 |

5.81 |

7.75 |

1286 |

6430 |

|

914 |

2.41 |

6.01 |

– |

– |

– |

840 |

4169 |

|

1219 |

5.38 |

13.60 |

– |

– |

– |

602 |

3010 |

|

span |

Uniform load (kg/m2) |

Recommended max. load |

Ultimate load |

||||

|

488 |

1220 |

2440 |

3660 |

4880 |

|||

|

457 |

0.32 |

0.98 |

1.62 |

2.26 |

3.25 |

7520 |

37620 |

|

610 |

0.99 |

2.28 |

4.86 |

6.80 |

9.70 |

4220 |

21090 |

|

914 |

4.51 |

– |

– |

– |

– |

1830 |

9160 |

|

1219 |

– |

– |

– |

– |

– |

– |

– |

Pultruded I-5010

|

span |

Line load (kg/m) |

Recommended max. load |

Ultimate load |

||||

|

149 |

373 |

745 |

1148 |

1490 |

|||

|

457 |

– |

– |

2.54 |

3.59 |

4.80 |

2760 |

13800 |

|

610 |

– |

1.90 |

4.08 |

6.05 |

8.15 |

2150 |

10760 |

|

914 |

2.25 |

5.71 |

11.70 |

17.50 |

23.25 |

1436 |

7180 |

|

1219 |

5.05 |

12.70 |

25.60 |

38.20 |

50.98 |

1070 |

5368 |

|

span |

Uniform load (kg/m2) |

Recommended max. load |

Ultimate load |

||||

|

488 |

1220 |

2440 |

3660 |

4880 |

|||

|

457 |

0.50 |

1.60 |

2.65 |

3.80 |

4.57 |

12100 |

60520 |

|

610 |

1.26 |

3.13 |

5.30 |

7.37 |

10.40 |

7080 |

35430 |

|

914 |

4.56 |

13.10 |

– |

– |

– |

3140 |

15716 |

|

1219 |

13.68 |

– |

– |

– |

– |

1760 |

8809 |

Pultruded Grating I-5015

|

span |

Line load (kg/m) |

Recommended max. load |

Ultimate load |

||||

|

149 |

373 |

745 |

1148 |

1490 |

|||

|

457 |

– |

0.50 |

0.99 |

1.50 |

1.75 |

4370 |

21856 |

|

610 |

0.26 |

0.89 |

1.50 |

2.30 |

3.28 |

3280 |

16400 |

|

914 |

0.74 |

1.90 |

3.80 |

5.55 |

7.60 |

2116 |

10580 |

|

1219 |

1.76 |

4.18 |

8.36 |

12.46 |

16.48 |

1514 |

7570 |

|

span |

Uniform load (kg/m2) |

Recommended max. load |

Ultimate load |

||||

|

488 |

1220 |

2440 |

3660 |

4880 |

|||

|

457 |

0.25 |

0.64 |

1.02 |

1.40 |

2.00 |

19100 |

95560 |

|

610 |

0.5 |

1.27 |

2.18 |

2.94 |

4.04 |

10780 |

53900 |

|

914 |

1.78 |

4.56 |

7.66 |

10.68 |

15.20 |

4630 |

23168 |

|

1219 |

4.56 |

12.60 |

– |

– |

– |

2490 |

12460 |

Pultruded Grating T-3320

|

span |

Line load (kg/m) |

Recommended max. load |

Ultimate load |

||||

|

149 |

373 |

745 |

1148 |

1490 |

|||

|

457 |

– |

– |

– |

– |

– |

– |

– |

|

610 |

– |

– |

0.51 |

0.74 |

1.06 |

3375 |

16876 |

|

914 |

– |

0.62 |

1.28 |

1.76 |

2.30 |

1500 |

7498 |

|

1219 |

0.49 |

1.27 |

2.26 |

3.52 |

4.82 |

845 |

4228 |

|

span |

Uniform load (kg/m2) |

Recommended max. load |

Ultimate load |

||||

|

488 |

976 |

2440 |

3660 |

4880 |

|||

|

457 |

– |

– |

– |

– |

– |

– |

– |

|

610 |

– |

0.38 |

0.50 |

0.64 |

1.000 |

11080 |

55400 |

|

914 |

0.52 |

1.16 |

1.90 |

2.68 |

3.80 |

7380 |

36900 |

|

1219 |

1.28 |

3.40 |

5.70 |

8.12 |

11.66 |

5570 |

27861 |

| Notes: 1, Safety factor is 5; 2, Ultimate load is the grating break load; 3, This table is only for information, resins and grating surfaces influence the grating loading property. | |||||||

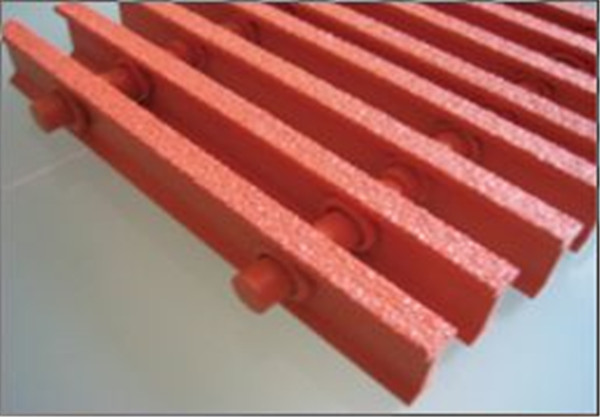

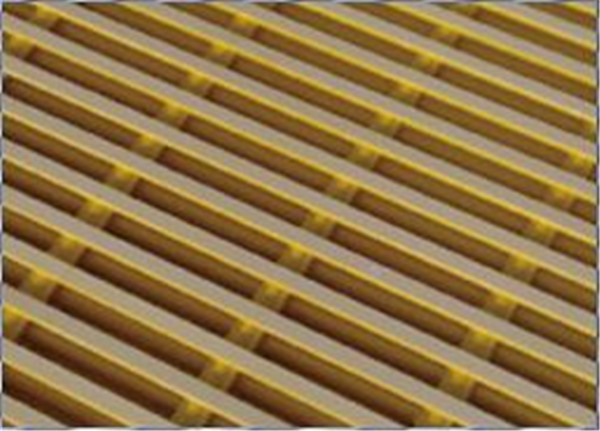

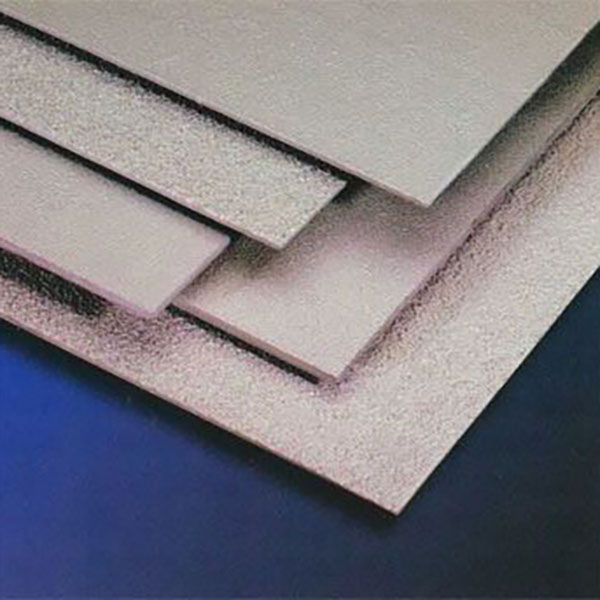

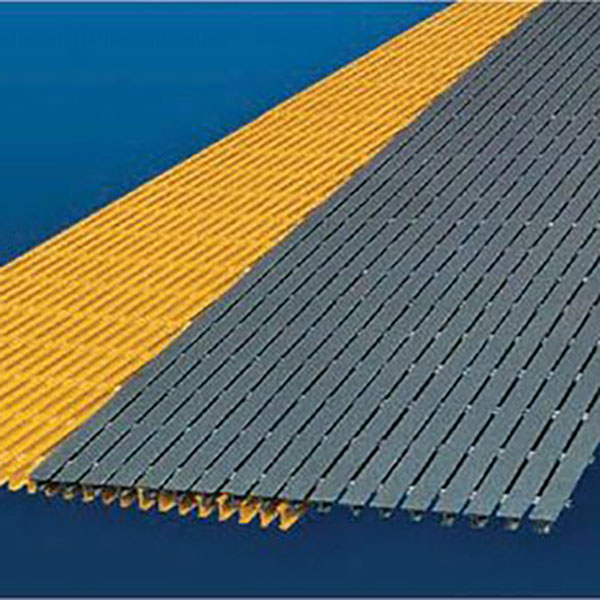

FRP Pultruded Grating Surface

|

Real |

Surface |

Service |

|

Corrugated surface (No grit) |

Anti-skid, easy clean |

|

|

Grit surface |

Anti-skid and good abrasion (The grit could be fine, middle and coarse) |

|

|

Smooth surface |

Free clean, contaminant non stay |

|

|

Chequer cover surface |

Anti-skid, easy clean, odour isolation |

|

|

Grit cover surface |

Anti-skid, good abrasion (The grit could be fine, middle and coarse), odour isolation |

Standard Resin Systems

|

ONFR |

Polyester resin system, Good corrosion resistance, Non fire resistance; |

|

OFR |

Polyester resin system, Good corrosion resistance, Fire resistance ASTM E-84 Class 1; |

|

ISOFR |

Premium grade Isophthalic Polyester resin system, excellent corrosion resistance, Fire resistance ASTM E-84 Class 1; |

|

VEFR |

Vinyl Ester resin system, Maximum corrosion resistance, Fire resistance ASTM E-84 Class 1; |

|

PHE |

Phenolic resin system, High temperature service, Low flame spread index, low smoke developed index and low toxicity. |

Chemical Properties

FRP Pultruded Grating Chemical Properties Guide:

|

Chemicals |

Concentration |

Maximum service temperature |

||

|

Vinyl ester resin |

Iso resin |

Ortho resin |

||

| Acetic acid |

50 |

82 |

30 |

20 |

| Chromic acid |

20 |

38 |

No |

No |

| Nitric acid |

5 |

70 |

48 |

25 |

| Phosphoric acid |

85 |

100 |

65 |

No |

| Sulfuric acid |

25 |

100 |

52 |

20 |

| Hydrochloric acid |

<10 |

100 |

52 |

No |

|

20 |

90 |

38 |

No |

|

|

37 |

65 |

No |

No |

|

| Hydrotropic acid |

25 |

93 |

38 |

No |

| Lactic acid |

100 |

100 |

52 |

40 |

| Benzoic acid |

All |

100 |

65 |

—— |

| Aluminum hydroxide |

All |

82 |

45 |

No |

| Aqueous ammonia |

28 |

52 |

30 |

No |

| Sodium hydroxide |

10 |

65 |

20 |

No |

|

25 |

65 |

No |

No |

|

|

50 |

70 |

No |

No |

|

| Ammonium sulfate |

All |

100 |

60 |

50 |

| Ammonium chloride |

All |

100 |

82 |

60 |

| Ammonium bicarbonate |

All |

52 |

No |

No |

| Copper chloride |

All |

100 |

65 |

60 |

| Copper cyanide |

All |

100 |

No |

No |

| Ferric chloride |

All |

100 |

65 |

60 |

| Ferrous chloride |

All |

100 |

60 |

50 |

| Manganese sulfate |

All |

100 |

65 |

45 |

| Sodium cyanide |

All |

100 |

—— |

—— |

| Potassium nitrate |

All |

100 |

65 |

40 |

| Zinc sulfate |

All |

100 |

65 |

45 |

| potassium nitrate |

100 |

100 |

65 |

40 |

| Potassium dichromate |

100 |

100 |

60 |

40 |

| Ethylene glycol |

100 |

100 |

65 |

40 |

| Propylene glycol |

100 |

100 |

65 |

40 |

| Gasoline |

100 |

80 |

60 |

35 |

| Glucose |

100 |

100 |

38 |

No |

| Glycerin |

100 |

100 |

65 |

60 |

| Hydrogen peroxide |

30 |

38 |

— |

— |

| Dry chlorine gas |

100 |

82 |

38 |

No |

| Wet chlorine gas |

All |

82 |

No |

No |

| Vinegar |

100 |

100 |

65 |

30 |

| Distilled water |

100 |

93 |

60 |

25 |

| fresh water |

100 |

100 |

70 |

40 |

| Note: the “All” in concentration column refers to the chemical is saturated in water; and the “100” refers to pure chemicals. | ||||

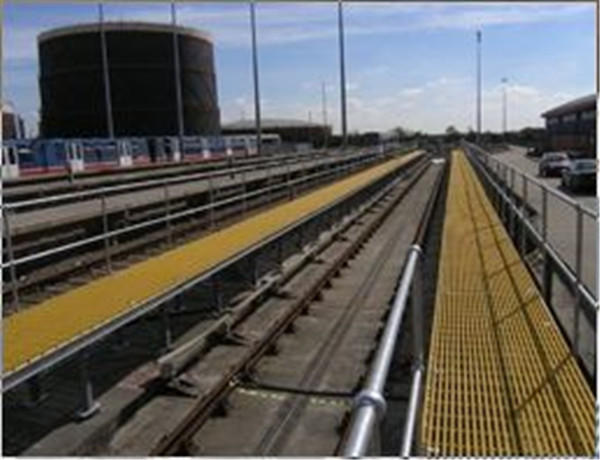

Product detail pictures:

Related Product Guide:

Our merchandise are broadly identified and trusted by end users and can satisfy continually developing economic and social requires for OEM Customized Heavy Duty Frp Grating - High Quality FRP GRP Pultruded Grating – WellGrid , The product will supply to all over the world, such as: panama, St. Petersburg, Lebanon, We hope we can establish long-term cooperation with all of the customers, and hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need!Welcome all customers both at home and abroad to visit our factory. We hope to have win-win business relationships with you, and create a better tomorrow.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.