OEM/ODM Factory Frp Grating Sizes - frp molded grating – WellGrid

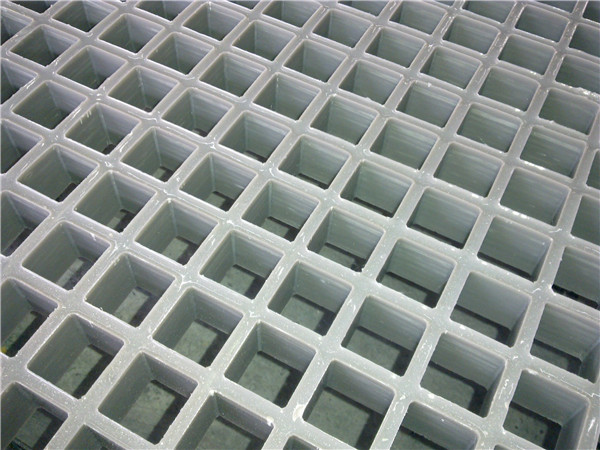

OEM/ODM Factory Frp Grating Sizes - frp molded grating – WellGrid Detail:

Advantages

1. Corrosion Resistance

Different types of resin provide their own different anti-corrosion properties, which could be used in different corrosion circumstance such as acid, alkali, salt, organic solvent (in gas or liquid form) and the like over a long period.

2. Fire Resistance

Our special formula provide grating with excellent fire resistant performance. Our FRP gratings pass ASTM E-84 Class 1.

3. Light Weight & High Strength

The perfect combination of the continuous E-glass roving and thermosetting polyester resin provide grating with light weight and high strength and its specific gravity is only 1/4 of that of steel, 1/3 of aluminum. Its rigidity is up to and even exceeds that of steel. Different thickness and mesh size bring the client more choice.

4. Safety & Anti-slip

The high modulus of elasticity and various surfaces provided the super anti-skid performances. Its surface could be smooth surface, meniscus surface, grit surface and chequer plate cover which is suitable for different working places.

5. Electrical Insulating

High strength E-glass roving and high-grade resin provide the product super electric performance. Its electric break strength could reach 10KV/mm. There is no electric spark even when impact by tools, meanwhile it is non-magnetism. FRP Molded Grating could be used safely under the antiknock, diamagnetism and electric-resistance environments.

6. Aging Resistance

The high-grade resin and anti-ageing stabilizer provide grating long-life ageing resistant performance and the unique design make grating excellent self-cleanness function and keep its brightness and strength over a long time. The service life of grating could be 25 years.

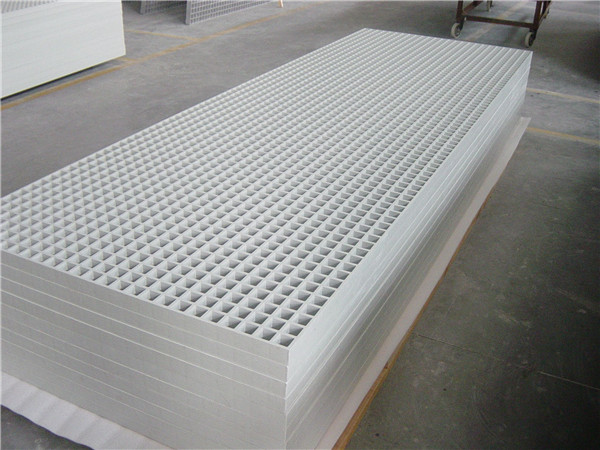

FRP Molded Grating Availability

|

No. |

Deep mm |

Mesh Size mm |

Panel Size Available mm (Width * Length) |

Open Area % |

Unit Weight (kg/m2) |

|

1 |

13 |

38*38 |

1220*3660 |

68 |

6.3 |

|

2 |

13 |

50*50 |

1220*3660 |

78 |

5.8 |

|

3 |

13 |

38*38+19*19 |

1220*3660 |

40 |

10.8 |

|

4 |

14 |

40*40+20*20 |

1007*4047 |

42 |

10.5 |

|

5 |

22 |

40*40+20*20 |

1007*4047 |

42 |

15.0 |

|

6 |

25 |

38*38 |

1220*3660/1000*4038 |

68 |

12.7 |

|

7 |

25 |

38*38+19*19 |

1220*3660 |

40 |

16.6 |

|

8 |

25 |

40*40 |

1007*4047 |

66 |

12.5 |

|

9 |

25 |

100*25 |

1007*3007 |

66 |

13.0 |

|

10 |

25 |

101.6*25.4 |

1220*3660 |

64 |

15.2 |

|

11 |

30 |

38*38 |

1220*3660/1000*4038 |

68 |

15.0 |

|

12 |

30 |

38*38+19*19 |

1220*3660/1000*4038 |

40 |

18.6 |

|

13 |

30 |

40*40+20*20 |

1007*4047 |

42 |

18.0 |

|

14 |

30 |

38*38+12*12*12 |

1220*3660/1000*4038 |

30 |

22.0 |

|

15P |

38 |

38*38 |

1525*3050/1220*3660/1000*4038 |

68 |

19.0 |

|

16 |

38 |

38*38+19*19 |

1220*3660/1000*4038 |

40 |

23.7 |

|

17 |

38 |

40*40+20*20 |

1007*4047 |

42 |

23.5 |

|

18 |

38 |

38*152 |

1220*3660 |

66 |

19.0 |

|

19 |

40 |

40*40 |

1007*4047 |

66 |

20.0 |

|

20 |

50 |

38*38 |

1220*3660 |

56 |

42.0 |

|

21 |

50 |

50*50 |

1220*3660 |

78 |

21.2 |

|

22 |

60 |

38*38 |

1220*3660 |

54 |

51.5 |

| Notes: the letter P following the No. means this grating could be supplied with phenolic resin. | |||||

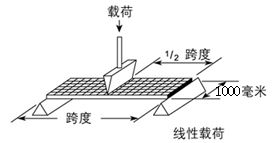

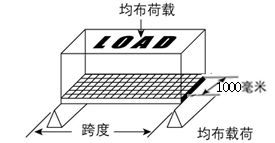

RP Molded Grating Loading Table

25mm 38x38mm

30mm 38x38mm

38mm 38x38mm

50mm 50x50mm

25mm 38x38mm

|

Span mm |

Concentrated Line Load (kg/m) |

Max Load |

|||||

|

75 |

150 |

300 |

450 |

600 |

750 |

||

|

450 |

0.559 |

1.146 |

2.159 |

3.073 |

4.115 |

4.75 |

3910 |

|

600 |

0.864 |

1.702 |

3.505 |

5.156 |

6.706 |

8.173 |

2924 |

|

900 |

2.896 |

5.918 |

12.116 |

18.44 |

—— |

—— |

1948 |

|

1200 |

5.715 |

11.633 |

—— |

—— |

—— |

—— |

1461 |

|

Span mm |

Uniform Load (kg/m2) |

Max Load |

|||||

|

240 |

480 |

980 |

1450 |

2450 |

3650 |

||

|

450 |

0.66 |

1.092 |

1.93 |

2.769 |

4.47 |

6.579 |

—— |

|

600 |

1.118 |

2.108 |

4.14 |

6.172 |

10.211 |

15.265 |

—— |

|

750 |

3.667 |

5.387 |

10.82 |

16.28 |

—— |

—— |

—— |

|

900 |

5.537 |

11.176 |

21.717 |

—— |

—— |

—— |

—— |

30mm 38x38mm

|

Span mm |

Concentrated Line Load (kg/m) |

Max Load |

|||||

|

75 |

150 |

300 |

450 |

750 |

1500 |

||

|

300 |

<0.254 |

<0.254 |

0.254 |

0.508 |

0.762 |

1.524 |

9923 |

|

450 |

0.254 |

0.508 |

1.106 |

1.524 |

2.54 |

—— |

4828 |

|

600 |

0.508 |

1.27 |

2.286 |

3.556 |

5.842 |

—— |

4112 |

|

750 |

1.27 |

2.54 |

4.826 |

7.366 |

12.446 |

—— |

3174 |

|

900 |

1.778 |

3.81 |

7.62 |

11.43 |

—— |

—— |

2637 |

|

Span mm |

Uniform Load (kg/m2) |

Max Load |

|||||

|

350 |

500 |

750 |

1000 |

1500 |

2500 |

||

|

300 |

<0.254 |

<0.254 |

<0.254 |

<0.254 |

0.254 |

0.508 |

32501 |

|

450 |

0.254 |

0.508 |

0.762 |

1.106 |

1.524 |

2.286 |

21661 |

|

600 |

1.016 |

1.524 |

2.286 |

2.794 |

4.318 |

7.366 |

12981 |

|

750 |

2.54 |

3.81 |

5.842 |

7.62 |

11.684 |

—— |

8396 |

|

900 |

4.572 |

7.112 |

10.668 |

—— |

—— |

—— |

5758 |

38mm 38x38mm

|

Span mm |

Concentrated Line Load (kg/m) |

Max Load |

|||||

|

75 |

150 |

300 |

450 |

600 |

750 |

||

|

300 |

0.279 |

0.356 |

0.483 |

0.61 |

0.762 |

0.889 |

17116 |

|

600 |

0.356 |

0.66 |

1.245 |

1.85 |

2.464 |

3.073 |

8718 |

|

900 |

0.864 |

1.803 |

3.683 |

5.563 |

7.417 |

9.296 |

5817 |

|

1200 |

2.261 |

4.749 |

9.677 |

14.63 |

19.583 |

—— |

3755 |

|

Span mm |

Uniform Load (kg/m2) |

Max Load |

|||||

|

240 |

480 |

980 |

1450 |

2450 |

3650 |

||

|

300 |

0.254 |

0.305 |

0.381 |

0.457 |

0.635 |

0.838 |

—— |

|

600 |

0.432 |

0.813 |

1.549 |

2.311 |

3.8354 |

5.74 |

—— |

|

900 |

1.702 |

3.454 |

6.959 |

10.465 |

17.475 |

—— |

—— |

|

1200 |

5.969 |

12.167 |

24.511 |

—— |

—— |

—— |

—— |

50mm 50x50mm

|

Span mm |

Concentrated Line Load (kg/m) |

Max Load |

|||||

|

75 |

150 |

300 |

450 |

600 |

750 |

||

|

300 |

0.279 |

0.305 |

0.406 |

0.483 |

0.635 |

1.041 |

21727 |

|

600 |

0.356 |

0.508 |

0.813 |

1.128 |

1.753 |

3.327 |

11713 |

|

900 |

0.508 |

1.118 |

2.235 |

3.2 |

5.156 |

10.058 |

7780 |

|

1200 |

0.914 |

1.93 |

3.937 |

5.918 |

9.957 |

—— |

5834 |

|

Span mm |

Uniform Load (kg/m2) |

Max Load |

|||||

|

240 |

480 |

980 |

1450 |

2450 |

3650 |

||

|

300 |

0.254 |

0.279 |

0.33 |

0.381 |

0.483 |

0.737 |

—— |

|

600 |

0.381 |

0.584 |

0.965 |

1.372 |

2.134 |

4.115 |

—— |

|

900 |

1.194 |

2.108 |

3.937 |

5.766 |

9.449 |

18.593 |

—— |

|

1200 |

2.413 |

4.928 |

9.954 |

14.961 |

—— |

—— |

—— |

RP Molded Grating Loading Table

|

Real |

Surface |

Service |

|

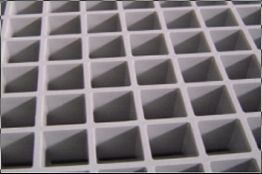

Concave surface |

Anti-skid, easy clean |

|

|

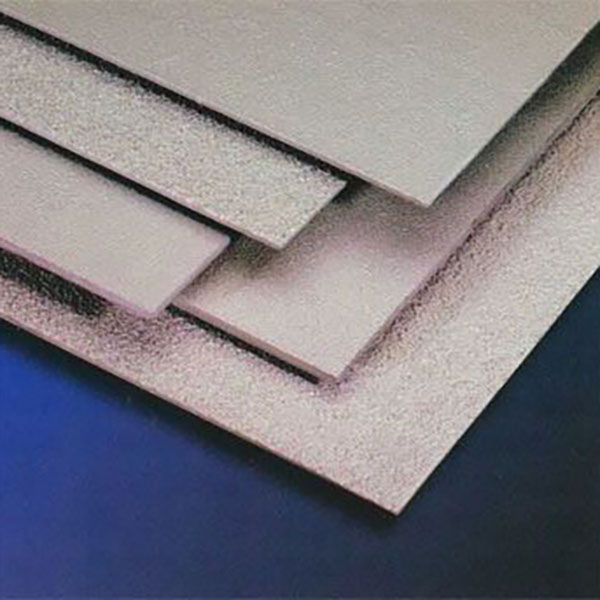

Grit surface |

Anti-skid and good abrasion (The grit could be fine, middle and coarse) |

|

|

Smooth surface |

Free clean, contaminant non stay |

|

|

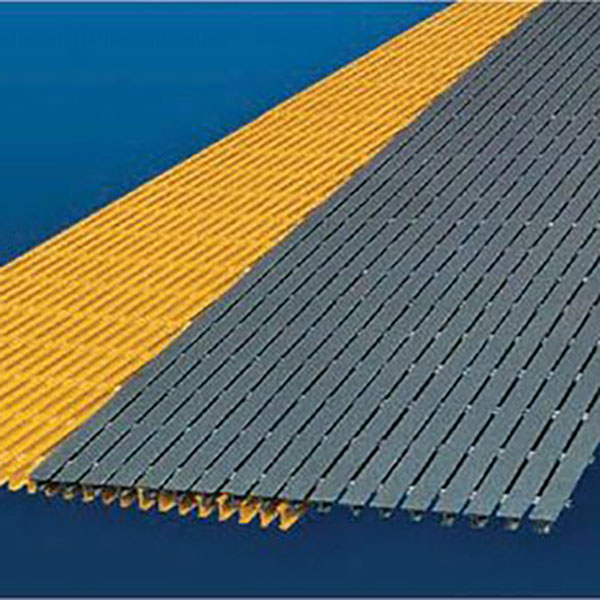

Chequer cover surface |

Anti-skid, easy clean, odour isolation |

|

|

Grit cover surface |

Anti-skid, good abrasion (The grit could be fine, middle and coarse), odour isolation |

Standard Resin Systems

|

ONFR |

Polyester resin system, Good corrosion resistance, Non fire resistance; |

|

OFR |

Polyester resin system, Good corrosion resistance, Fire resistance ASTM E-84 Class 1; |

|

ISOFR |

Premium grade Isophthalic Polyester resin system, excellent corrosion resistance, Fire resistance ASTM E-84 Class 1; |

|

VEFR |

Vinyl Ester resin system, Maximum corrosion resistance, Fire resistance ASTM E-84 Class 1; |

|

PHE |

Phenolic resin system, High temperature service, Low flame spread index, low smoke developed index and low toxicity. |

Chemical Properties

FRP Molded Grating Chemical Properties Guide

|

Chemicals |

Concentration |

Maximum service temperature |

||

|

Vinyl ester resin |

Iso resin |

Ortho resin |

||

| Acetic acid |

50 |

82 |

30 |

20 |

| Chromic acid |

20 |

38 |

No |

No |

| Nitric acid |

5 |

70 |

48 |

25 |

| Phosphoric acid |

85 |

100 |

65 |

No |

| Sulfuric acid |

25 |

100 |

52 |

20 |

| Hydrochloric acid |

<10 |

100 |

52 |

No |

|

20 |

90 |

38 |

No |

|

|

37 |

65 |

No |

No |

|

| Hydrotropic acid |

25 |

93 |

38 |

No |

| Lactic acid |

100 |

100 |

52 |

40 |

| Benzoic acid |

All |

100 |

65 |

—— |

| Aluminum hydroxide |

All |

82 |

45 |

No |

| Aqueous ammonia |

28 |

52 |

30 |

No |

| Sodium hydroxide |

10 |

65 |

20 |

No |

|

25 |

65 |

No |

No |

|

|

50 |

70 |

No |

No |

|

| Ammonium sulfate |

All |

100 |

60 |

50 |

| Ammonium chloride |

All |

100 |

82 |

60 |

| Ammonium bicarbonate |

All |

52 |

No |

No |

| Copper chloride |

All |

100 |

65 |

60 |

| Copper cyanide |

All |

100 |

No |

No |

| Ferric chloride |

All |

100 |

65 |

60 |

| Ferrous chloride |

All |

100 |

60 |

50 |

| Manganese sulfate |

All |

100 |

65 |

45 |

| Sodium cyanide |

All |

100 |

—— |

—— |

| Potassium nitrate |

All |

100 |

65 |

40 |

| Zinc sulfate |

All |

100 |

65 |

45 |

| potassium nitrate |

100 |

100 |

65 |

40 |

| Potassium dichromate |

100 |

100 |

60 |

40 |

| Ethylene glycol |

100 |

100 |

65 |

40 |

| Propylene glycol |

100 |

100 |

65 |

40 |

| Gasoline |

100 |

80 |

60 |

35 |

| Glucose |

100 |

100 |

38 |

No |

| Glycerin |

100 |

100 |

65 |

60 |

| Hydrogen peroxide |

30 |

38 |

— |

— |

| Dry chlorine gas |

100 |

82 |

38 |

No |

| Wet chlorine gas |

All |

82 |

No |

No |

| Vinegar |

100 |

100 |

65 |

30 |

| Distilled water |

100 |

93 |

60 |

25 |

| fresh water |

100 |

100 |

70 |

40 |

| Note: the “All” in concentration column refers to the chemical is saturated in water; and the “100” refers to pure chemicals. | ||||

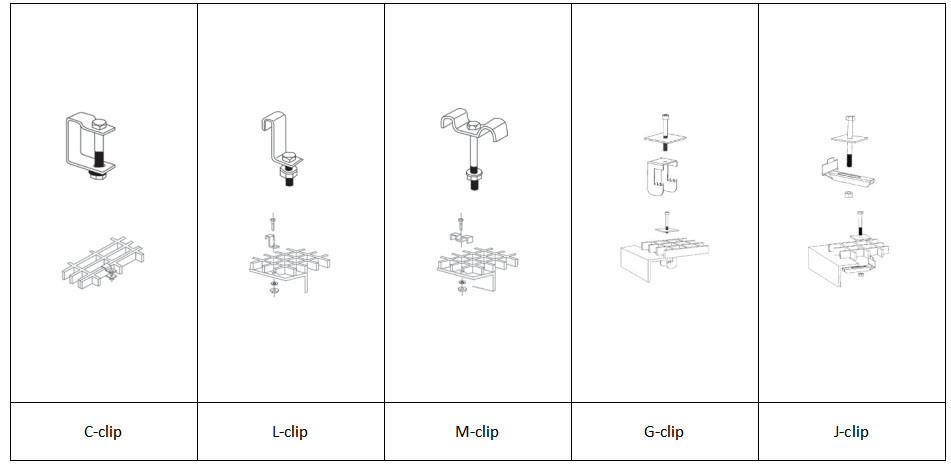

Hold down Clips: Stainless steel holds down clips are one of our services to our clients.

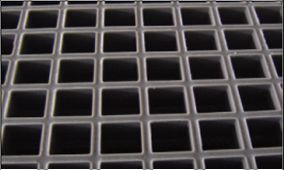

Product detail pictures:

Related Product Guide:

With our leading technology at the same time as our spirit of innovation,mutual cooperation, benefits and advancement, we will build a prosperous future with each other with your esteemed firm for OEM/ODM Factory Frp Grating Sizes - frp molded grating – WellGrid , The product will supply to all over the world, such as: Honduras, Ukraine, kazakhstan, Qualified R&D engineer will be there for your consultation service and we will try our best to meet your requirements. So please feel free to contact us for inquiries. You'll be able to send us emails or call us for small business. Also you are able to come to our business by yourself to get further knowing of us. And we will surely give you the best quotation and after-sale service. We're ready to build stable and friendly relations with our merchants. To achieve mutual success, we will make our best efforts to build a solid co-operation and transparent communication work with our companions. Above all, we are here to welcome your inquiries for any of our goods and service.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.