Short Lead Time For Fibreglass Channel - FRP Hand Layup Product – WellGrid

Short Lead Time For Fibreglass Channel - FRP Hand Layup Product – WellGrid Detail:

Hand Layup Process

Gel coating

Gel coating gives you the smoothness required for the product. It is usually a thin layer of resin that is about 0.3 mm on the surface of the product. Adding proper pigments to the resin, and the color is custom available. The gel coating forms a protective layer to protect the products from contacting with water and chemicals. If it is too thin, the fiber pattern will become visible. If it is too thick, there will be crazing and star cracks on the product’s surface.

Surface mat layer

The surface mat layer will be placed under the gel coating. The fiber of the mat is not as strong as the reinforced fiber, but the mat provides the anti-crack and impact strength for the rich resin layer. This is an optional layer that is only used in a particular situation.

Fiberglass laminate

The resin wetted Fiberglass layer shall be laid in sequence until the required thickness is reached. The finished material is called a lamination. Laminate gives the fiberglass product strength and rigidity. Fiberglass in the chopped strand mat (CSM) are usually used for obtaining composite material products. Woven roving, one-way mat and two-way mat are also used for acquiring high strength materials.

Surface mat layer/resin coating

Fiberglass laminate provides a rough surface finish. In order to obtain a smoother surface, we can apply a surface mat or resin coating to the laminate and smooth it by placing a thin layer.

Advantages

This is a low-volume, labor-intensive method. It’s suitable for many fiberglass reinforced plastic products, such as FRP vessel, fiberglass car bodies, FRP pipe, FRP tank, furniture, corrosion resistant FRP equipment. No expensive machinery is necessary. Almost all shapes and sizes can be made. The color and texture can be obtained through the hand layup method. Choosing composite layup process as a FRP process. As a GRP manufacturing method, the following conditions are good for hand layup. Only one side needs to have a smooth surface. The product has large size and complex shape. Only a small amount of components are needed.

|

|

|

Flower Pot |

Waste Water Cover |

|

Air Conditioning Cover |

Radome Cover |

|

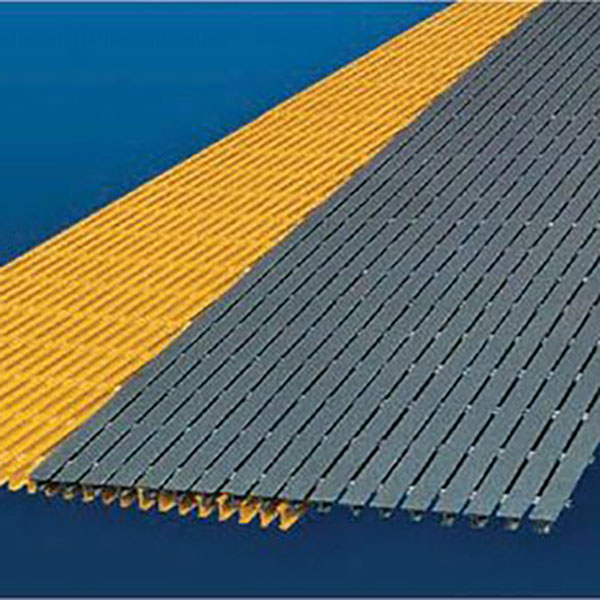

Flat sheet |

Engine Cover |

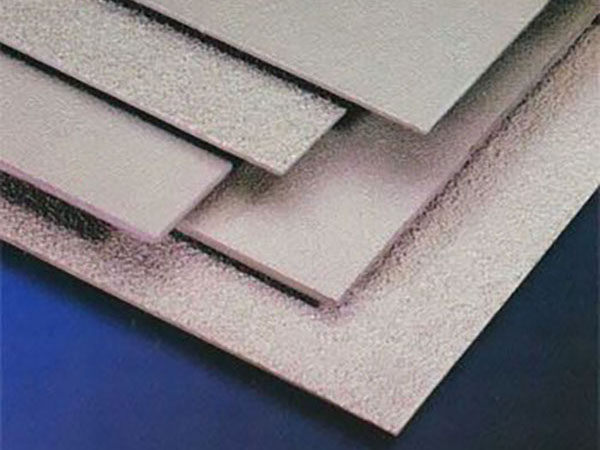

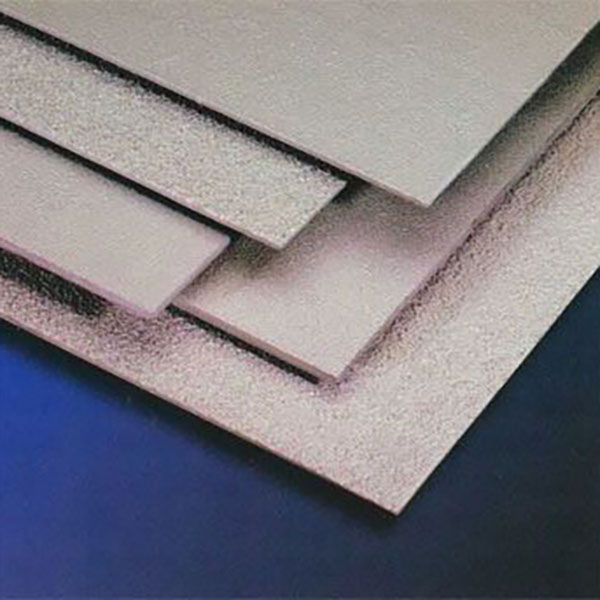

FRP Molded Plate: Our standard fiberglass plate thickness could be 3-25mm, the standard plate size could be 1000*2000mm, 1220*2440mm, and custom requirement plate is available with request.

Product detail pictures:

Related Product Guide:

We have been ready to share our knowledge of advertising worldwide and recommend you suitable products at most aggressive costs. So Profi Tools present you ideal price of money and we've been ready to create with each other with Short Lead Time For Fibreglass Channel - FRP Hand Layup Product – WellGrid , The product will supply to all over the world, such as: Venezuela, Tunisia, Wellington, We've got constantly insisted on the evolution of solutions, spent good funds and human resource in technological upgrading, and facilitate production improvement, meeting the wants of prospects from all countries and regions.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.